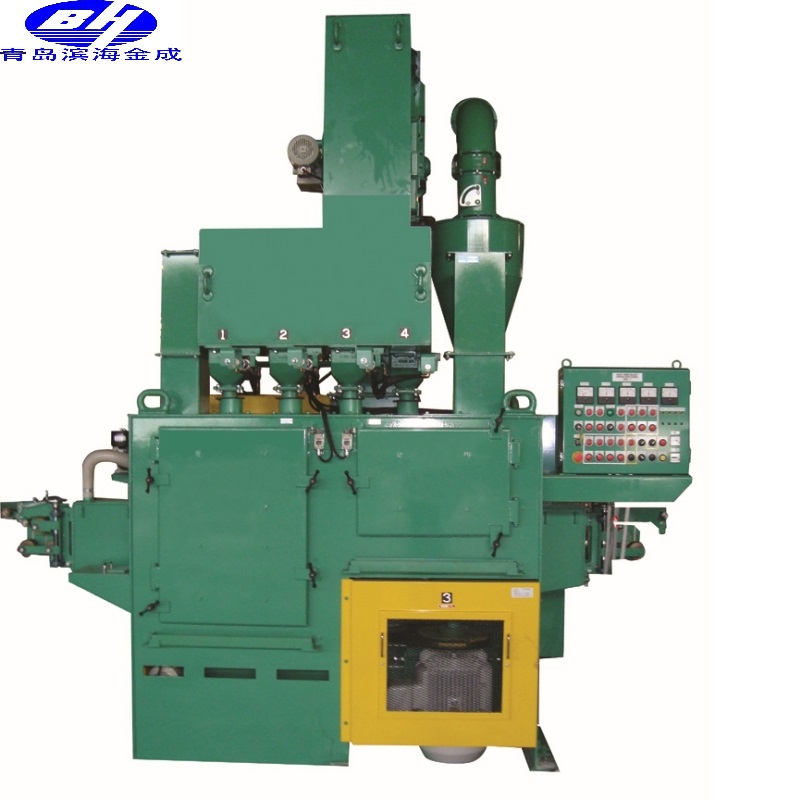

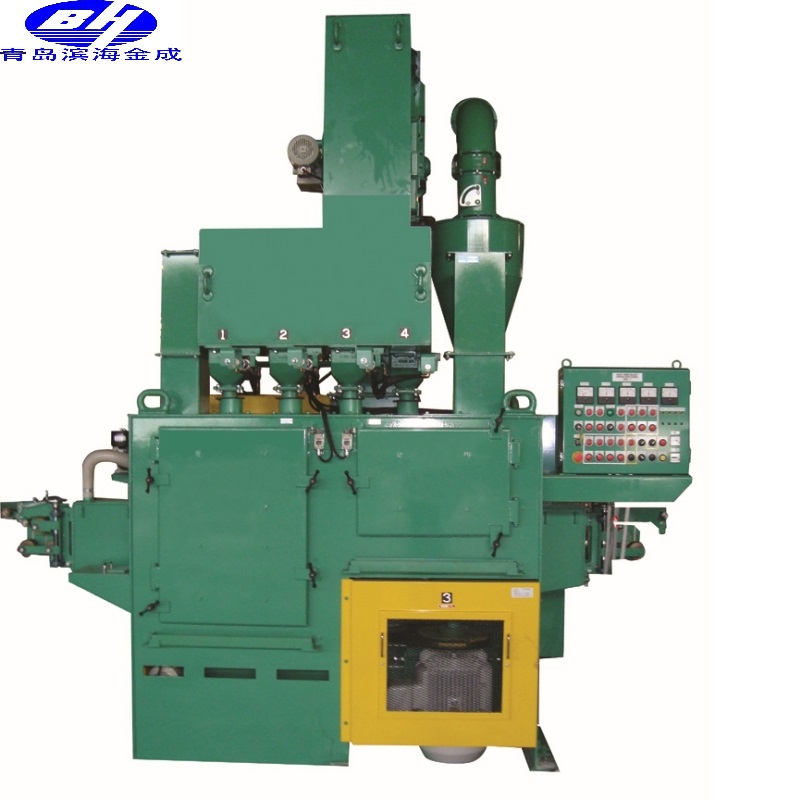

Shot blasting machine (Single machine)

-

Q341 Series Reinforced Shot Blasting Machine

Summary

Q341 series Reinforced shot blasting machine is also called hook-turntable multi-station shot blasting machine. It is a new type shot blasting machine which is independently developed by our company.

This series of products is an upgraded products of the Q37 Series Hook type Shot Blasting Machine in our company’s General series of products.

Adopts 2stations design, which can realize the process of loading and unloading the work-pieces in another station while one station is being shot blasted.

Mainly used for surface cleaning or strengthening treatment of small forgings, castings and structural parts. Especially suitable for the work-pieces which easy to hang and shot from the side and the top, such as motor housings, connecting rods, gear shafts, cylindrical gears, clutch diaphragms, bevel gears and other products.

Through shot blasting, not only can remove molding sand, rust, oxide, welding slag, etc. on the surface of the work-piece, it can greatly improve the surface hardness of the part, can improve the internal stress of the work-piece, achieve the purpose of strengthening, improve the work-piece Fatigue resistance. More, It can make the work-pieces obtain a uniform metallic luster, and improve the coating quality and anti-corrosion effect of the work-piece. -

Q35 Series Turn Table type Shot Blasting Machine

Summary

Q35 Series Turn Table type Shot Blasting Machine is suitable for surface treatment of small batch castings, forgings and heat treatment parts. Also can strengthen the surface of work-pieces according to the requirements of customers. Especially suitable for the surface cleaning of the work-piece which has the feature of flat; thin wall and fear collision.

Q35M Series 2 stations Turn Table type Shot Blasting Machine is Q35 Series upgraded products.

(Q35M) The turntable is installed on the revolving door with bearing. With the opening of the door, the turntable will turn out. It is very convenient to take and place the work-piece.

Generally applicable to the work-pieces with cleaning requirements only for one side (flat parts). -

QM Series Anchor Chain Shot Blasting Machine

Summary

QM Series Anchor Chain Shot Blasting Machine is a special type shot blasting cleaning equipment for Anchor Chain. After shot blasting by this machine, it will remove the oxides and attachments on the surface of the anchor chain, And by the causing plastic deformation on its surface, effectively improve the fatigue strength and corrosion resistance of anchor chain.Greatly increases the adhesion of the paint film. -

Mobile type Shot Blasting Machine for Paves

Summary

The Floor shot blasting machine is the shot blasting machine ejects the shot material (steel shot or sand) at a high speed and a certain angle onto the working surface through a mechanical method.

The shot material fully impacts the working surface to achieve the rough surface and remove residues. At the same time, the negative pressure generated by the dust collector will clean the pellets and the cleaned impurity dust etc. after the airflow, the intact pellets will be automatically recycled, and the impurities and dust will fall into the dust collection box. -

Hook Type Shot Blasting Machine

Machine Usage: Hook type shot blasting machine is suitable for cleaning the foundry part, construction, chemical engineering, machine tools and many other industries of large, medium size castings and forgings surface cleaning.it is the most popular type cleaning machine. We apply this cleaning technology to achieve the purpose of derusting, strengthen Eliminate internal stress Improve surface adhesion Descaling improve the fatigue resistance Prolong its service life Before cleaning Afte... -

Steel Plate Shot Blasting Machine

Steel Plate Shot Blasting Machine strongly blast the sheet metal and profiles to remove surface rust, welding slag and scale, making it slow uniform metal color, improve coating quality and corrosion prevention effect. Its processing range from 1000mm to 4500mm, and it can easily integrated intro preservation lines for automatic painting.

-

Shot blasting machine for Steel track with large specification

Product Description This crawler type shot blasting machine is one of the standard series of cleaning equipment. It can be used to clean casting, forging and welding parts, and remove the sand and oxide scale on the surface of the workpiece. Due to the good protective measures of the machine, the good performance of the shot blasting machine, and the reasonable structure of the projectile circulation system, satisfactory results can also be obtained for materials and workpieces that are diffi... -

Tunnel type shot blasting machine profile

Tunnel type shot blasting machine profile It also can named hook pass through type shot blasting machine This type of cleaning machine is suitable for the surface cleaning of large and medium-sized castings, forgings and structural parts in casting, construction, chemical, motor, machine tool and other industries. Tunnel type shot blasting machine application We use shot blasting technology to achieve the purpose of derusting and strengthening, because shot blasting is still the most economi... -

Function of catenary type shot blasting machine

Function of catenary type shot blasting machine Q38,Q48,Q58 series catenary stepping shot blasting machine used to remove castings, forgings, structural parts such as the workpiece surface sand, scale, rust and so on. The surface of the workpiece appears metallic luster, and castings surface defects exposed to eliminate the stress within the workpiece, the surface roughness to Ra12.5 requirements GB6060.5 requirements, in line with national JB / T8355-96 Sa2.5 level. Main model specification... -

QWD Series Mesh Belt Type Shot Blasting Machine

Summary

QWD series Mesh Belt Shot Blasting Machine is a new type of equipment which is independently developed by our company.

In terms of cleaning equipment classification, it should belongs to Q69 Series Pass-Through type Shot Blasting Machine.

Mainly used for the surface shot blasting machine of thin-walled castings; iron or aluminum alloy castings which has the feature of thin-walled and fragile; ceramics and other small parts, and also for strengthening the work-pieces.

It has the characteristics of good continuity, high cleaning efficiency, small deformation, no need the foundation for the machine, etc. it can be used alone or in combination with the production line. -

XQ Series Wire Rods Shot Blasting Machine

Summary

XQ Series wire rods shot blasting machine is belong to special industry equipment, adopts full protection structure, and design the machine doesn’t need the foundation.

It is equipped with strong power Impeller Head in the cleaning room for wire rods.

The surface of the wire after shot blasting by this machine presents a uniform roughness, increases the adhesion of the aluminum-clad; copper clad. Will Makes the cladding uniform and does not fall off.

Eliminates the internal stress generated during the wire drawing process.

Increases the tensile strength and resistance of the wire surface Stress corrosion cracking performance, to obtain permanent service life. -

BHLP series Mobile–Portable type Shot Blasting Machine

Summary:

Pavers shot blasting machine is a special equipment for pavers roughing which is dedicated designed by our company for the pavers processing industry.

It is mainly used to increase the friction coefficient of the pavers surface and improve the surface decoration effect. After being processed by pavers shot blasting machine, the surface of the pavers will show an effect similar to that of litchi surface.

It is widely used in the fields of marble wall hanging and anti-skid on the ground. For the moment, more and more ground paving prefers the rough surface, has a board market prospect.