China OEM Turn Table Shot Blasting Machine For Cleaning Casting Parts - Q341 Series Reinforced Shot Blasting Machine – Binhai Jincheng

China OEM Turn Table Shot Blasting Machine For Cleaning Casting Parts - Q341 Series Reinforced Shot Blasting Machine – Binhai Jincheng Detail:

1.Overview:

Q341 series Reinforced shot blasting machine is also called hook-turntable multi-station shot blasting machine. It is a new type shot blasting machine which is independently developed by our company.

This series of products is an upgraded products of the Q37 Series Hook type Shot Blasting Machine in our company’s General series of products.

Adopts 2stations design, which can realize the process of loading and unloading the work-pieces in another station while one station is being shot blasted.

Mainly used for surface cleaning or strengthening treatment of small forgings, castings and structural parts. Especially suitable for the work-pieces which easy to hang and shot from the side and the top, such as motor housings, connecting rods, gear shafts, cylindrical gears, clutch diaphragms, bevel gears and other products .

Through shot blasting, not only can remove molding sand, rust, oxide, welding slag, etc. on the surface of the work-piece, it can greatly improve the surface hardness of the part, can improve the internal stress of the work-piece, achieve the purpose of strengthening, improve the work-piece Fatigue resistance. More, It can make the work-pieces obtain a uniform metallic luster, and improve the coating quality and anti-corrosion effect of the work-piece.

Customized according to different work-pieces, non-standard design and manufacturing.

2.Working principle:

This series of products usually contains 2 stations, one is the loading and unloading station; the other is the shot blasting station, these two stations are interchangeable.

After loading the work-pieces in the loading and unloading stations, it will stop after reaching the shot blasting station driven by the turntable. At this time, the other station can continue to load or unload.

The work-pieces of the shot blasting station starts to rotate under the action of the hook. The shot blasting machine begin to work.

After the cleaning is completed, the loading and unloading station and the shot blasting station are exchanged. Repeat till all the work-pieces are cleaned.

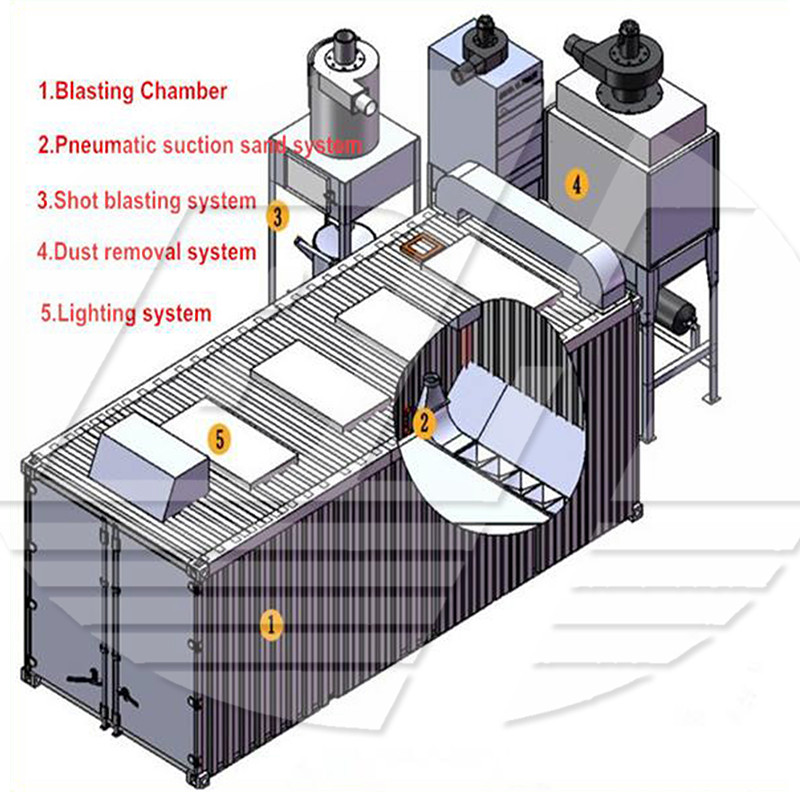

3.Machine Compositions:

Q341 Series Reinforced Shot Blasting Machine (The hook-turntable shot blasting machine) is composed of: Shot blasting cleaning room; Turntable; Bucket Elevator; Separator; Screw Conveyor; Shot Blaster Assembly; Hook and Platform; Hook Rotation Reduction Device; Turntable Revolution Device; and Steel Shot Supply System; Dust Removal System; Electrical Control System; etc.

4.Main technical parameters:

|

NO. |

Item |

Parameter |

Unit |

|

1 |

Max. loading for single hook |

280 |

kg |

|

2 |

Max.dimension of work-piece |

φ56(EX Diameter)/300 |

mm |

|

φ28(IN Diameter)/300 |

mm |

||

|

3 |

Total blast volume of the impeller head |

2*180 |

kg/min |

|

Total power of the impeller head |

2*11 |

kW |

|

|

Blasting speed of the impeller head |

70-80 |

m/s |

|

|

4 |

Lifting capacity of the bucket elevator |

30 |

T/H |

|

Power of the bucket elevator |

3.00 |

KW |

|

|

5 |

Fractional dose of the separator |

30 |

T/H |

|

6 |

Delivery value of Screw conveyor |

30 |

T/H |

|

7 |

Rotation rotary speed |

2.7 |

r/min |

|

Rotation power |

0.37 |

kW |

|

|

8 |

Revolution rotary speed |

2.5 |

r/min |

|

Revolution power |

0.75 |

kW |

|

|

9 |

Blasting capacity of the dust removal |

7000 |

m3/h |

|

Power of the dust removal |

4 |

kW |

|

|

10 |

First charge weight of Steel shot |

0.5 |

T |

|

Diameter of the steel shot |

f 0.5-0.8 |

mm |

|

|

11 |

Total power |

~30 |

kw |

5.Advantages of the products:

A.Global Design:

Simulated shot diagram (including the determination of the model, number and spatial arrangement of the impeller head) and all drawings of the shot blasting machine are completely drawn by computer-aided design (CAD).

After many times of practical experience optimize, to achieve a more perfect shot effect.

It will ensure that on the basis of covering all the work-pieces to be cleaned, the empty throwing of the steel shot is minimized, thereby maximizing the utilization rate of the steel shot and reducing the wear on the protective plate in the cleaning room.

B.Cleaning Room:

The body of the shot blasting cleaning room adopts welded structure, and is made of steel plate and structural steel.

The body of the cleaning room is made of high-quality Q235A steel plate (thickness 8-10mm). The inner wall is lined with 10mm thick “Rolled Mn13” protective plate, and adopts “Block type” protective plate layout.

Rolled Mn13 plate is the best choice for wear-resistant materials with the features of strong impact resistance, high pressure material wear, etc, with “lifetime” reputation, and there isn’t has any other wear-resistant materials can match Its work hardening.

The large hexagon nut which is used for fixing the protective plate is made of special cast iron, and its structure has a larger contact surface with the protective plate.

C.Impeller Head:

Using large shot blasting capacity (Q037; Shinto. Japan shot blasting technology, the latest technology on the market); with high-speed blasting centrifugal shot blasting device can significantly improve the cleaning efficiency and obtain satisfactory cleaning quality.

The top protective plate and side protective plate of the shot blasting machine all adopt special structure, and the local thickness reaches 70mm, which greatly improves the wear resistance and service life of the protective plate.

D.Separator:

Adopting advanced “BE” type full-curtain separator. The separator is mainly composed of sorting area, conveying screw, steel shot bin, steel shot control gate, etc.

This separator was independently developed by our company on the basis of completely absorbed the technology of Swiss GEORGE FISCHER DISA (GIFA) and American Pangborn company. It is the latest type of separator of our company.

The separation efficiency can reach 99.9%.

The separator is one of the key components of this equipment. The design size of the separation zone directly affects the separation effect of the separator. If the separation effect is not good, it will accelerate the wear of the blast blades, reduce its service life, and increase maintenance costs.

E.Steel shot circulation system:

The steel shot circulation system of the whole equipment adopts automatic detection device. When a part is not running smoothly or stuck, it can automatically alarm and notify the faulty part, so that the maintenance personnel can carry out targeted maintenance.

F. Targeted optimization

At both ends of the bucket elevator, separator, and screw conveyor adopts a labyrinth sealing device and a U-shaped boss structure.

The separation screw and screw conveyor discharge ports are arranged at a distance from the end. And the reverse conveying blade is added at the end of the screw.

Adopts the above structure, can improve the protection of the bearing and prolong its service life.

G.Dust removal system

Using high-efficiency pulse bag dust collector, the dust emission is within 30mg / m3, and the workshop dust emission is within 5mg / m3, which greatly improves the worker’s operating environment.

H.Humanized design

The loading and unloading station is equipped with a grating with safety protection function. Under abnormal conditions, any part of the operator’s body enters the grating area, and the turntable stops rotating immediately to avoid injury to the operator.

The work-piece to the loading station through the hook, then turn to the shot blasting station to stop, and clean while rotating. The degree of automation is high, the sealing effect is good, and the labor intensity of the worker is greatly reduced.

I.Reducer (maintenance-free)

All reducers use maintenance-free grease lubrication, which avoids the oil leakage of traditional oil-lubricated reducers and reduces lubrication maintenance costs.

J.Comprehensive structure

The structure of the equipment is compact, the layout is reasonable, and the maintenance is very convenient.

1.More information, please contact us!

6.RAQ:

There are so many kinds of shot blasting machines, in order to provide the best solutions for your products, please let us know the answers of the following questions:

1.What’s the products which you want to treatment? Had better show us your products.

2.If there are many types of products need to be treated, What’s the biggest size of the work-piece? Length * width * height?

3.What’s the weight of the biggest work-piece?

4.What’s the production efficiency do you want?

5.Any other special requirements of the machines?

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for China OEM Turn Table Shot Blasting Machine For Cleaning Casting Parts - Q341 Series Reinforced Shot Blasting Machine – Binhai Jincheng , The product will supply to all over the world, such as: Nepal, Anguilla, Swansea, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!